Tim Scheiwe

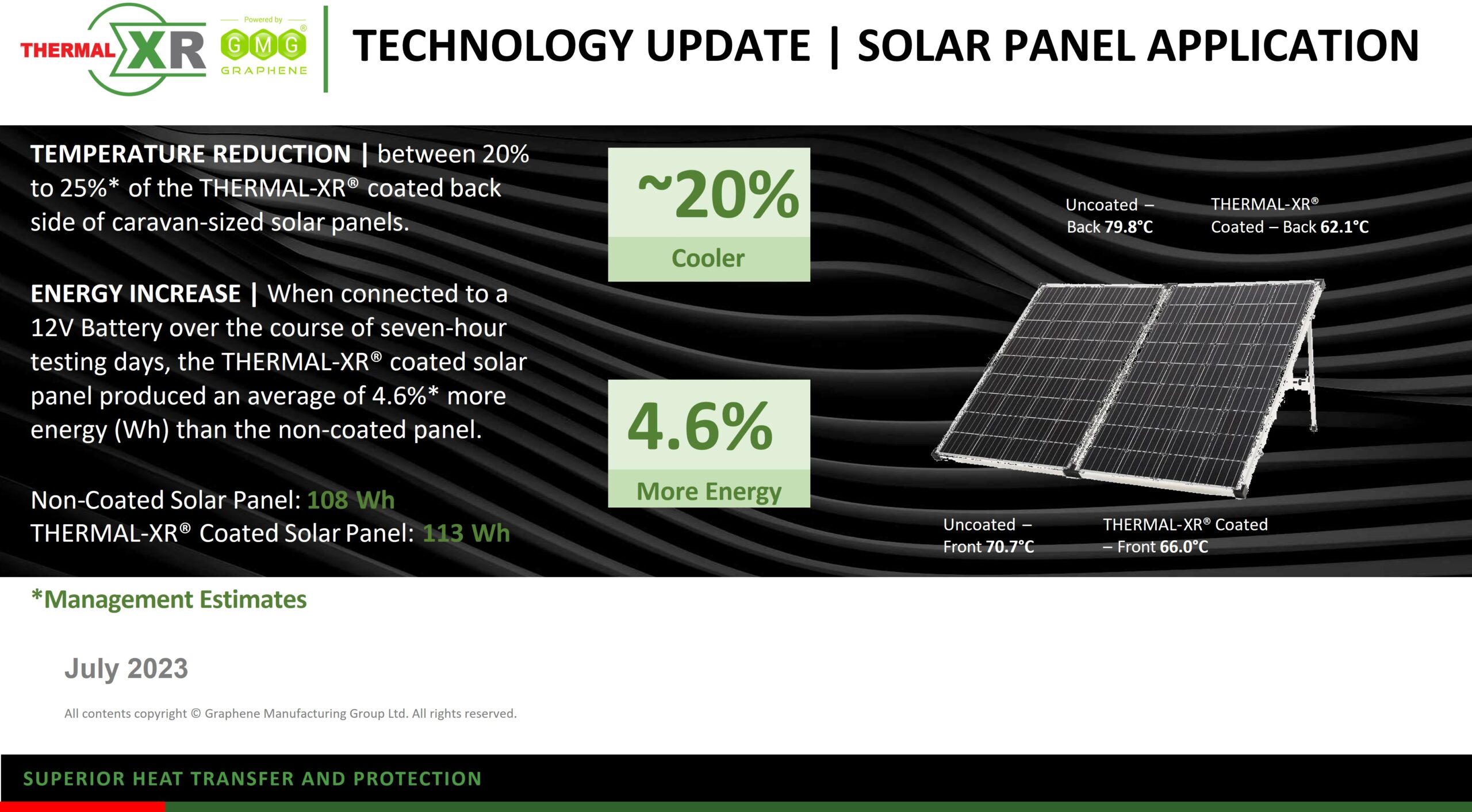

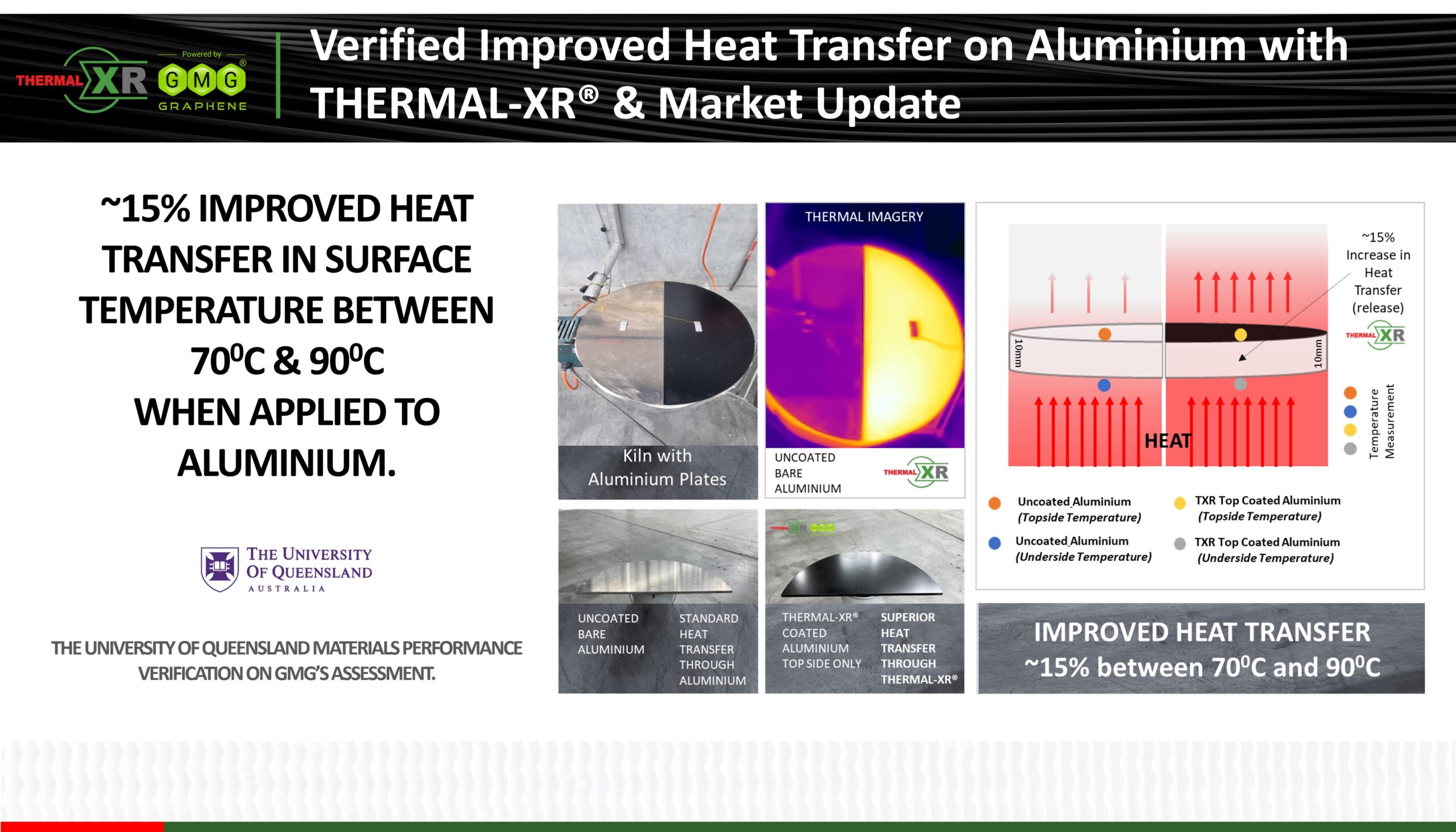

THERMAL-XR® LNG COATING SYSTEM is a unique method of improving the conductivity of corroded heat exchange surfaces and maintaining the performance of new units at peak levels. The process coats and protects heat exchange surfaces while improving and rebuilding the lost corroded thermal conductivity and increasing the heat transfer rate by leveraging the physics of GMG Graphene resulting in an efficiency improvement and a power reduction.

THERMAL-XR RESTORE® is powered by GMG Graphene.

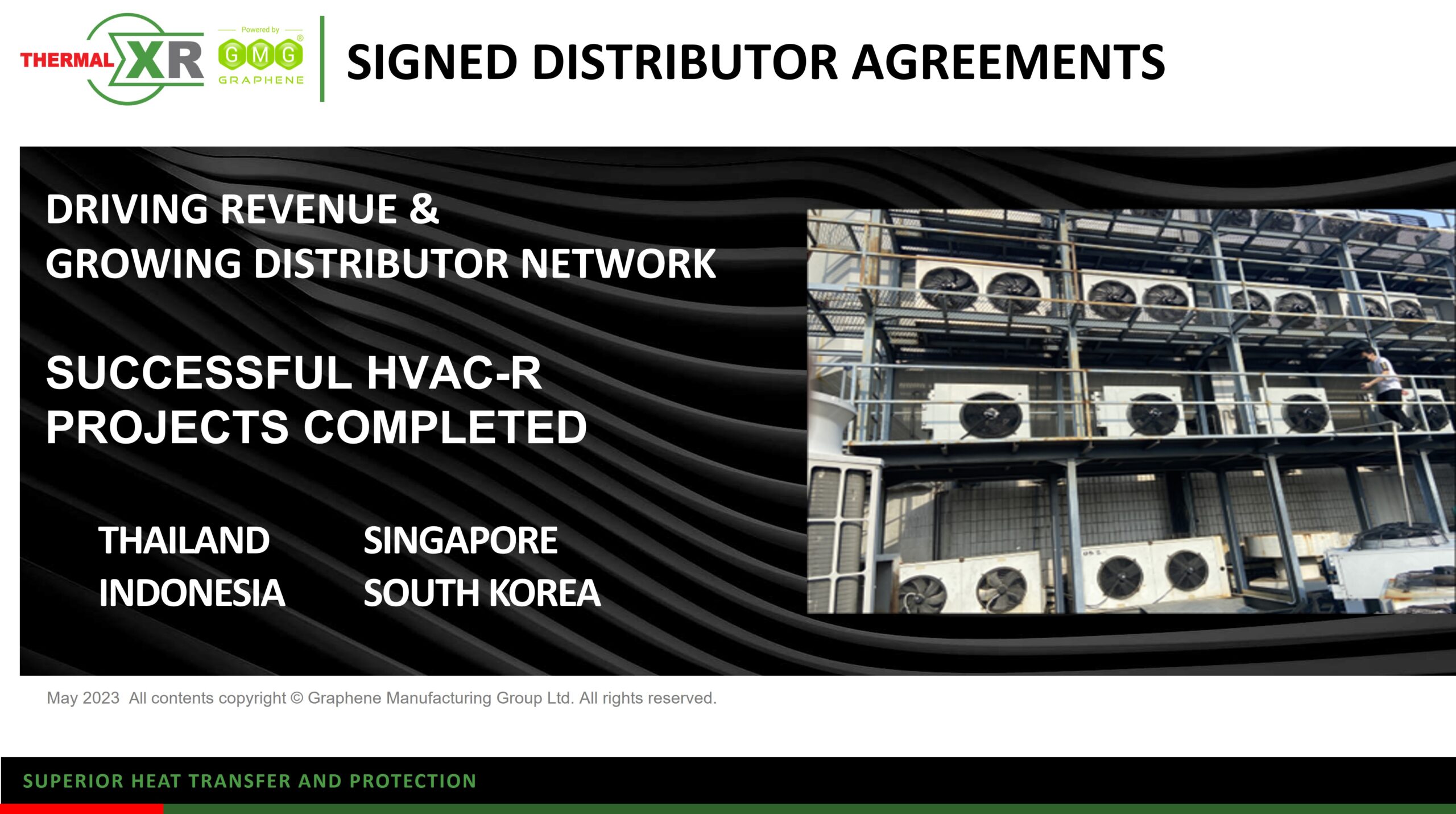

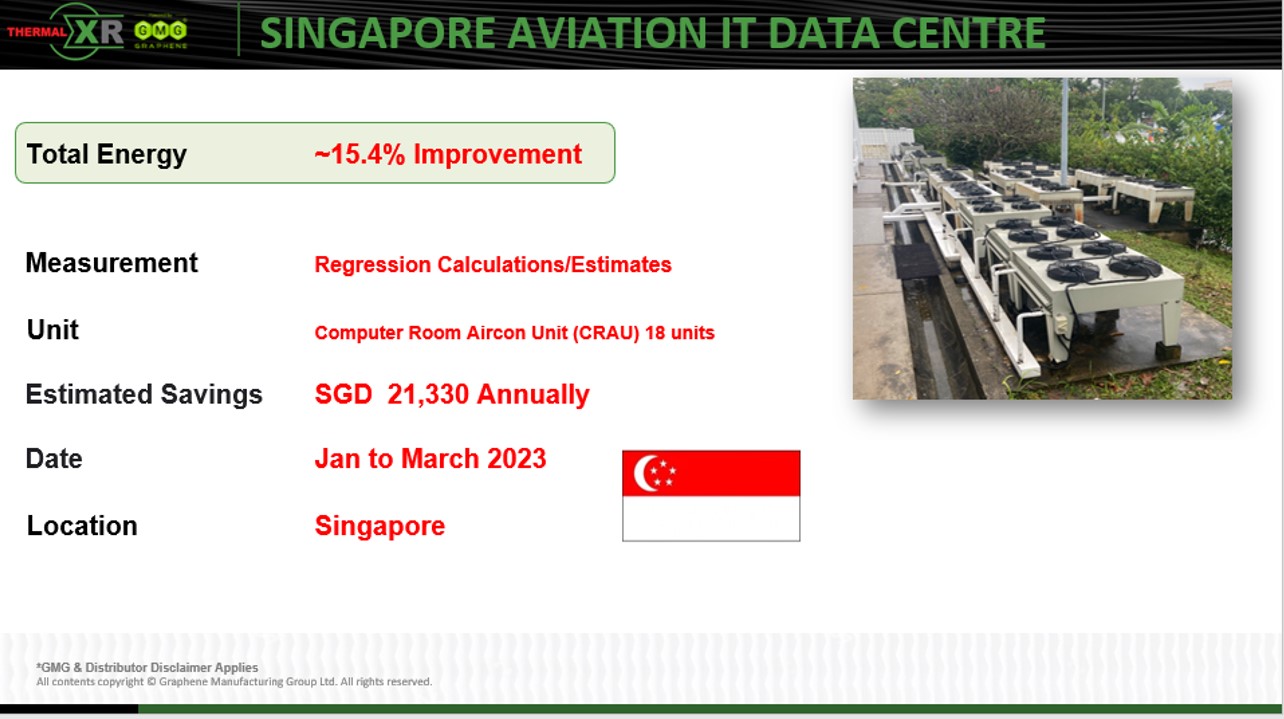

THERMAL-XR® HVAC can also protect both RTPF coils (round tube plate fin) and MCHC coils (microchannel) from accelerated corrosion damage, thereby extending the life of the coil and reducing energy consumption.

PATENT PENDING.

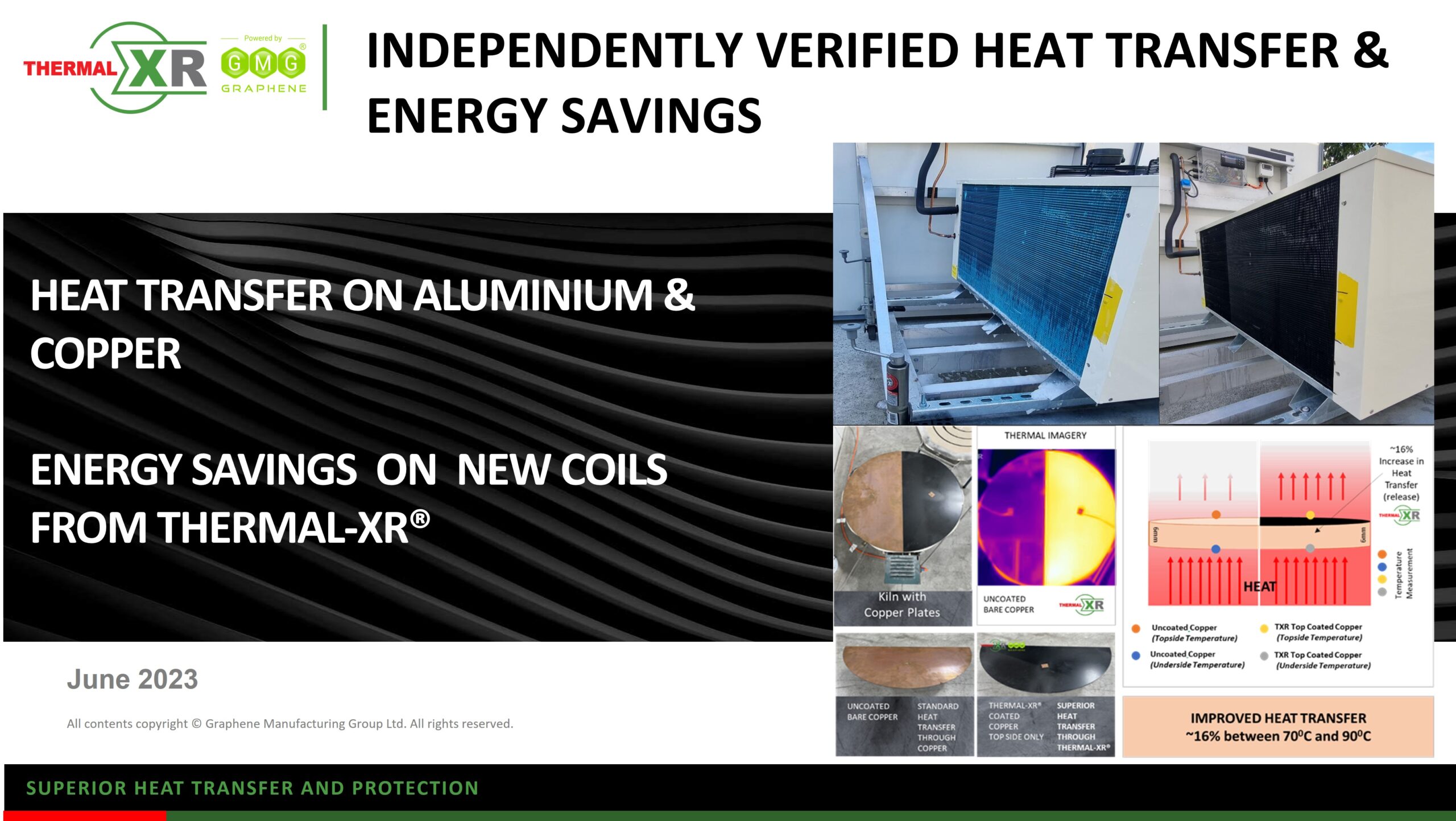

Heat exchangers are used in numerous industries where metal heat exchangers are required.

THERMAL-XR® has been used in industry, commercial, and residential applications.

Up to 300m 2 of micro surface area per gram of Graphene enables increased heat dissipation within the thin coating layer of THERMAL XR RESTORE ®.

GMG graphene creates an impervious layer that prevents oxygen from reaching metal surfaces, eliminating metal corrosion. Additionally, leveraging Graphene’s hydrophobic (water repellence) properties increases protection.

Graphene is reported to have a thermal conductivity 10-15 times greater than aluminium and copper, increasing heat dissipation across a system’s condenser coil.

Helps to reduce compressor operation times leading energy reduction.

THERMAL-XR® leverages GMG Graphene’s thermal properties to provide improved heat transfer and superior cooling performance.

The THERMAL-XR® Demonstration Centre brings together the beneficial elements of the THERMAL-XR® coating systemfor GMG Partners to experience first hand .

● Water Repellence

● Corrosion Protection

● Heat Transfer

● Energy Savings

THERMAL-XR® is suitable for applying on aluminium and copper coils used in air cooled heat exchange equipment, namely air conditioning and refrigeration.https://www.youtube.com/watch?v=swBlbxDwEE8&list=PL17v7tFwLezYieVnGoJicYnNqf3vPLKKf&index=1&t=33s

THERMAL-XR® RESTORE is a water-based acrylic resin impregnated with thermally conductive GMG

Graphene applied by high pressure spray gun.

Updates

Frequently Asked Questions

The results vary subject to the climate, age and deterioration of the equipment, cleanliness of the equipment, heating and cooling load and the health of the equipment.

How do I get more information?

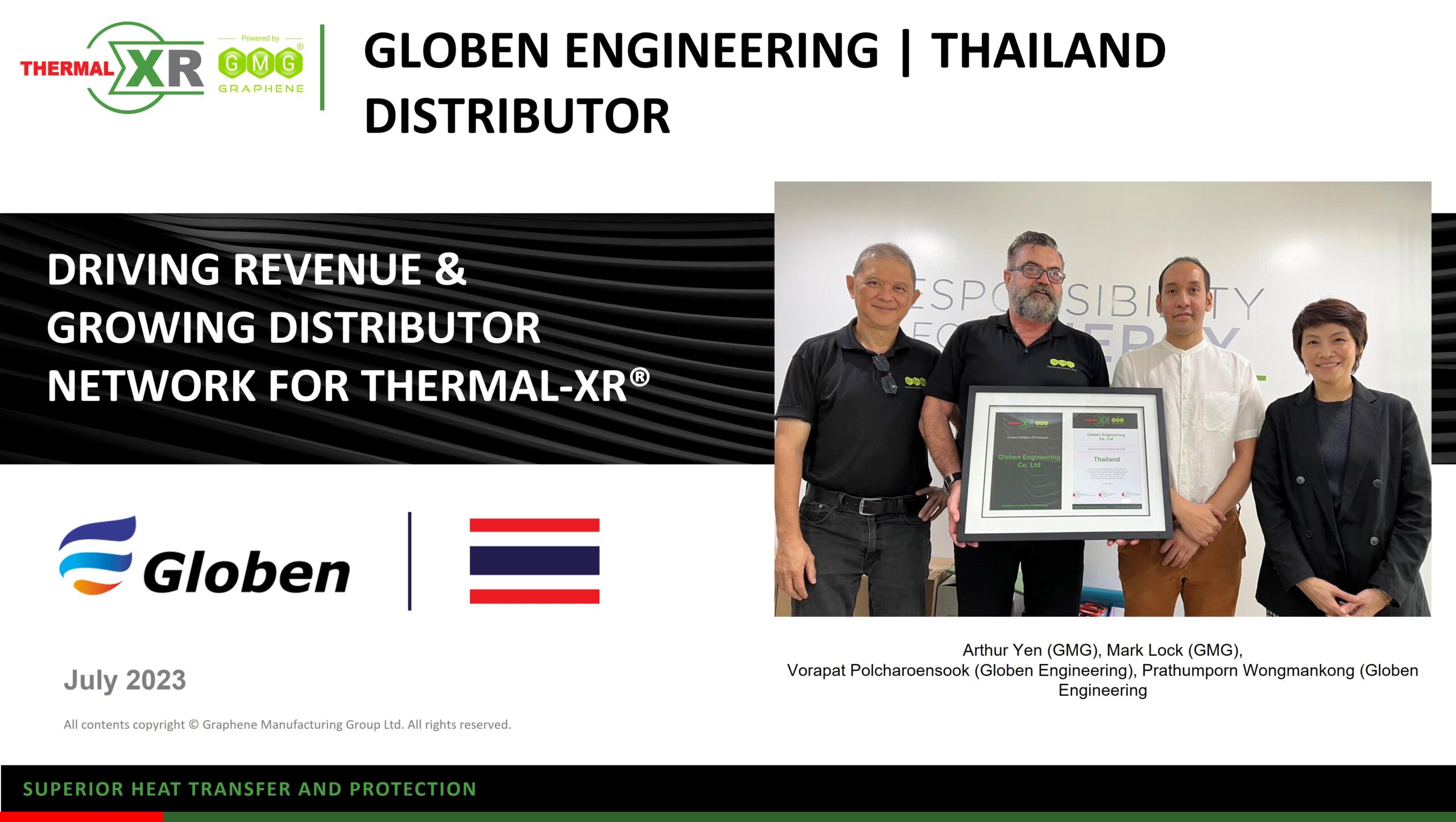

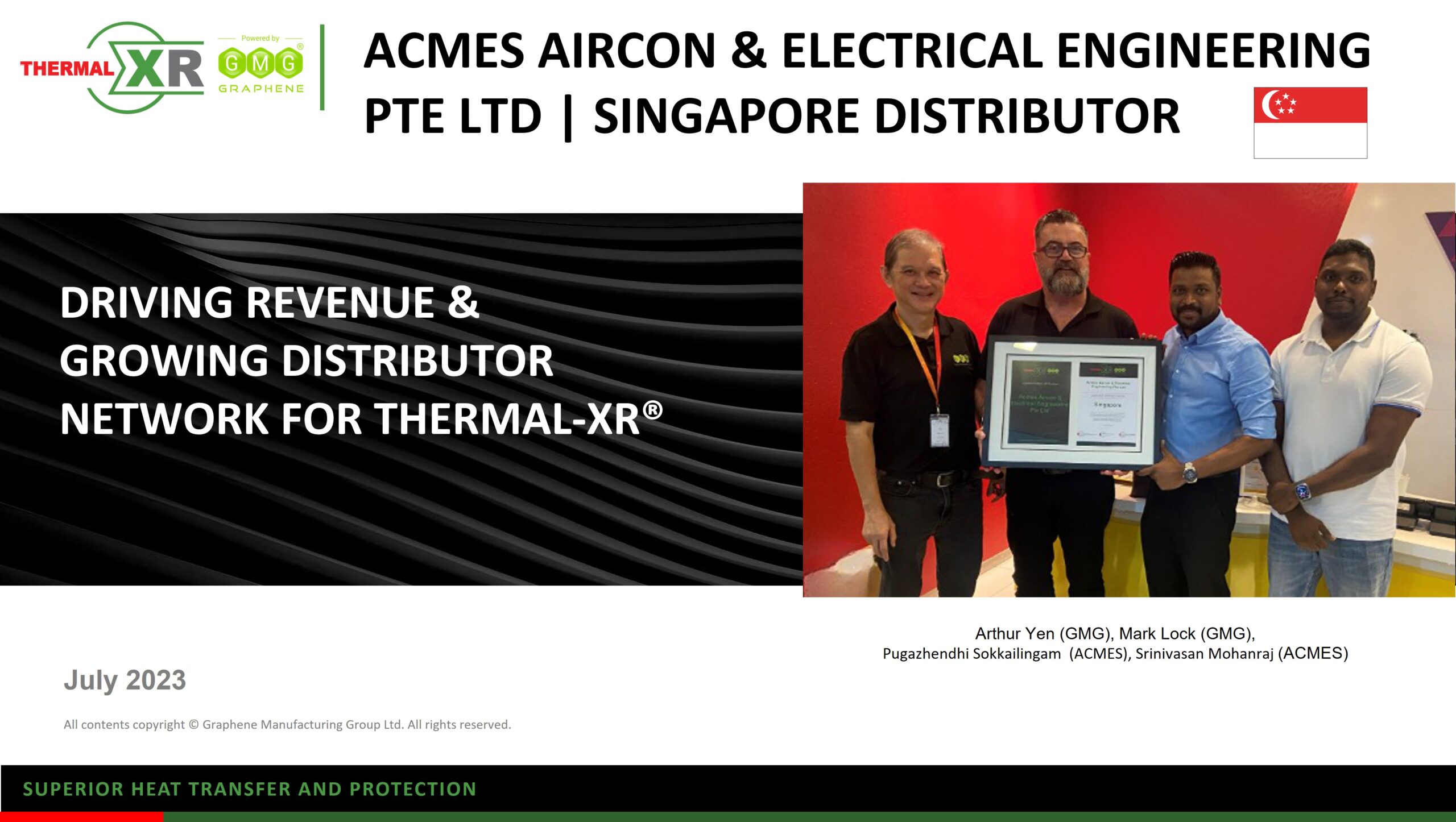

Please get in touch with GMG or our local distributor or partner for more information.

Will a black paint absorb sun radiation and become hotter?

THERMAL-XR® is powered by GMG Graphene and leverages graphene to remove heat, whereas black pigment in most black paints absorbs and retains heat. THERMAL-XR® works like a heat pump to transfer heat, whereas black paint typically performs as a paint insulator to retain heat in the paint and the substrate it is applied to.

Is the specific THERMAL-XR® coating for diffferent industries?

THERMAL-XR® HVAC is formulated for HVAC applications.

GMG is developing specific industry formulations to match industry applications and conditions.

How does THERMAL-XR® LNG differ?

GMG has a specific formulation for LNG plants conditions.

Enables superior heat transfer on heat exchangers to alleviate capacity reduce due to excessive heat.