BRISBANE, QUEENSLAND, AUSTRALIA – Graphene Manufacturing Group Ltd. (TSX-V:GMG; FRA:0GF) (“GMG” or the “Company”) is pleased to announce the appointments of Lisa Roobottom as Chief Operating Officer (“COO”) and Paul Mackintosh as Chief Health, Safety, Environment, Quality, Risk and Sustainability Officer (“Chief HSE, Risk & Sustainability Officer”), effective on the on the 30th day January, […]

BRISBANE, QUEENSLAND, AUSTRALIA – December 12, 2022 – Graphene Manufacturing Group Ltd. (TSX-V:GMG) (“GMG ” or the “Company”) is pleased to provide an update on its ongoing investment in the Company’s Battery Development Centre (“BDC”). The GMG Board has approved an additional $AU 600,000 in capital expenditure, to accelerate the progress of semi-automatic pouch cell […]

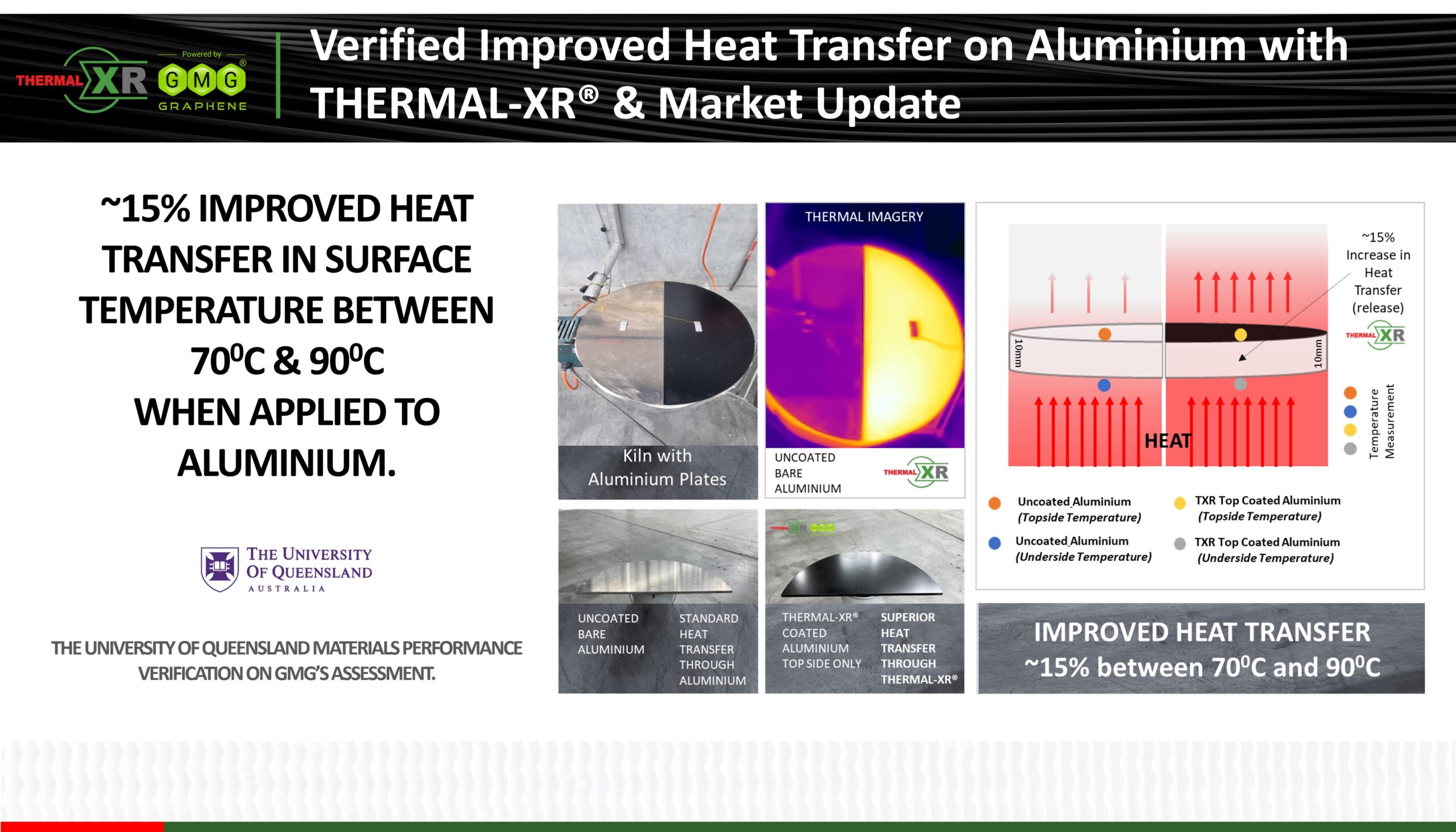

BRISBANE, QUEENSLAND, AUSTRALIA – Graphene Manufacturing Group Ltd. (TSX-V:GMG) (“GMG” or the “Company”) is pleased to release results of heat transfer demonstrations of Aluminium coated with THERMAL-XR® (TXR) powered by GMG Graphene, compared to uncoated bare Aluminium. The University of Queensland Materials Performance consultancy (“UQMP”) verified that GMG’s THERMAL-XR® when applied to aluminium reduces […]

GMG CEO & Managing Director, Craig Nicol, will be presenting at the Queensland Investment Showcase | INVESTING IN QUEENSLAND ENERGY session Friday 7th October at the Brisbane Convention The Queensland Investment Showcase will be held at the Brisbane Convention and Exhibition Centre (BCEC) on the Boulevard Level. Full conference details https://www.investmentshowcase.qld.gov.au/ [email protected] | www.graphenemg.com | TSXV: […]

GMG‘s Graphene to be used in world leading Biofabrication Institute: https://3dprint.com/232120/herston-biofabrication-institute-to-research-graphene/

Want to know how GMG can mix our Graphene into any bulk material ? This photo shows how we do it – by using our own dispersion technology – which completely disperses our Graphene (normally water repelling) into a fluid which then can be mixed into any bulk material. The laser is fully absorbed by […]

The world’s most exciting new super-material, graphene, will super charge Australian medical research as part of a Herston Biofabrication Institute study starting early next year. Researchers working on a range of 3D biomedical treatments plan to investigate the use of the miracle substance to help create better future health outcomes for Queenslanders. Graphene is a […]

McKinsey: Graphene a disruptive technology that will transform life, business and the global economy

chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://www.mckinsey.com/~/media/mckinsey/business%20functions/mckinsey%20digital/our%20insights/disruptive%20technologies/mgi_disruptive_technologies_full_report_may2013.pdf

https://www.goldmansachs.com/insights/pages/advanced-materials-craig-sainsbury.html