Why Do My Air Conditioning Units Need a HVAC Coil Coating?

Graphene Manufacturing Group explains why you should invest in a HVAC coil coating for your air conditioning systems.

Air conditioning systems are important assets in many businesses, and are relied upon to keep products, customers and employees cool or warm depending on the season. Because they are an expensive asset, it is understandable that you would want to ensure your systems are working at an optimal level, and that their lifespan is maximised. An effective way to achieve both goals is to apply a HVAC coil coating to your air conditioning unit.

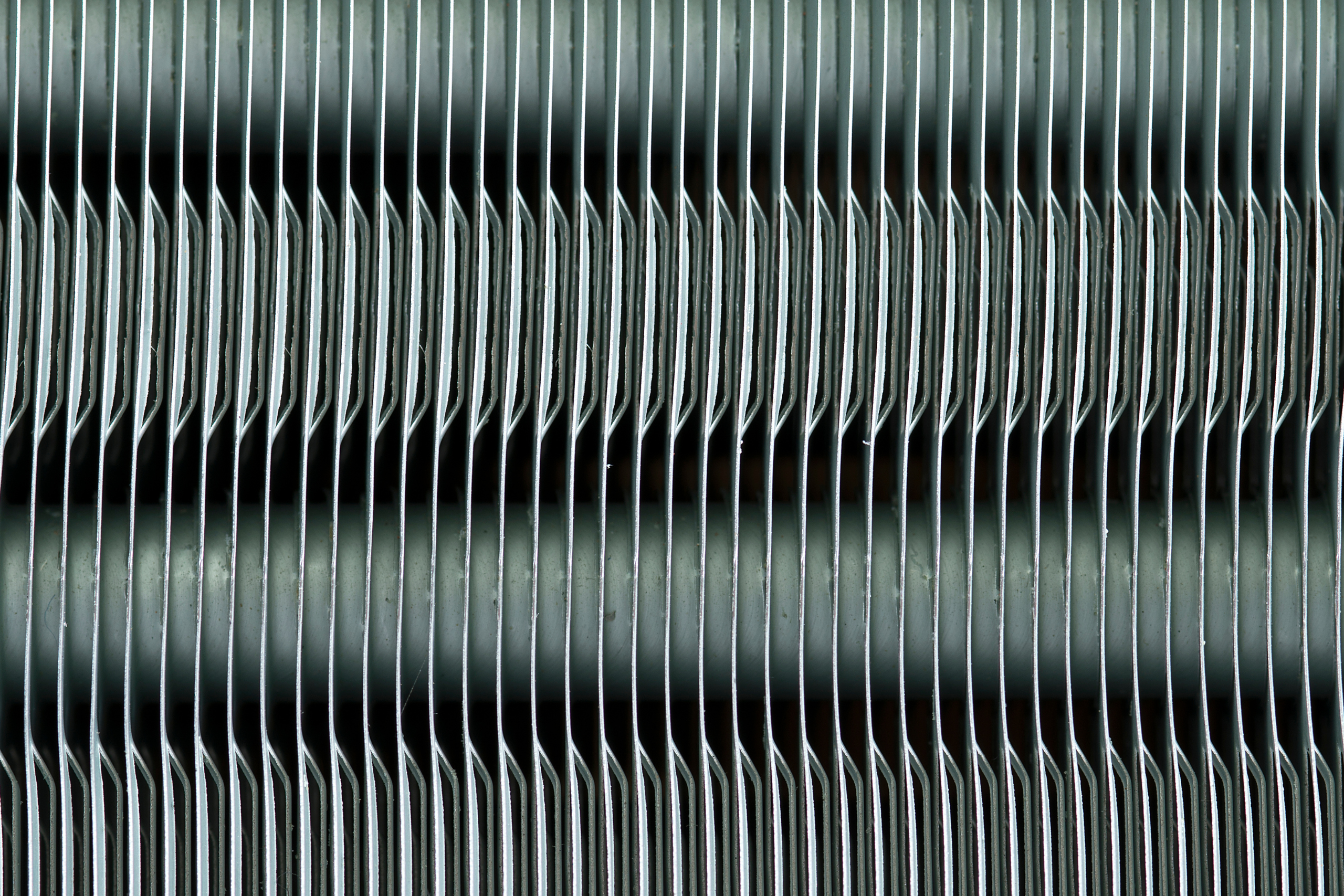

HVAC coils are heat exchange components in air conditioning systems that facilitate the transfer of thermal energy. They play a crucial role in either cooling or heating air as it passes through the system, ensuring proper temperature regulation. Thus, the maintenance and optimisation of these coils is paramount to the efficiency of your air conditioning systems.

In this blog, we explain how coating the coils can improve your HVAC system.

Corrosion Protection

Corrosion can negatively affect the energy efficiency of HVAC coils and result in higher maintenance or replacement costs. To combat this, HVAC coatings achieve corrosion protection by forming a protective barrier on the coil surfaces, effectively shielding them from corrosive elements. The coating acts as a barrier against moisture, pollutants and harsh weather conditions, preventing these elements from reaching and corroding the metal surfaces of the coils. For example, THERMAL-XR® is a highly concentrated combination de-ruster, degreaser and phosphator, formulated to treat and protect aluminium coils.

Because heat transfer is a major factor in the effectiveness of a HVAC system, promoting a more efficient exchange of energy between the coil and surrounding air can dramatically improve its functionality. HVAC coatings, especially those powered by graphene, optimise the heat transfer process, and by doing this, enhance efficiency levels by creating faster and more efficient temperature regulation with the system.

Energy Efficiency Improvement

Improved heat transfer, thanks to HVAC coil coatings, directly translates to energy savings – and therefore, cost savings on your energy bill. Furthermore, when the coils are free from contaminants due to the protection provided by these coatings, air conditioning systems don’t have to work as hard to cool the air. This results in even lower energy consumption and reduced HVAC costs.

Reduced Maintenance Requirements

Reduced maintenance is an attractive upside of applying a HVAC coil coating, and could save your business a lot of money in this area. Coated coils are much less prone to accumulating dirt and debris, which makes them easier to clean and maintain. This not only saves time and effort, but also minimises downtime for maintenance. Graphene coating, THERMAL-XR®, shows reduced heat pressures, temperatures and reduced compressor running time to setpoint which could extend the life of mechanical components – effectively reducing replacement costs as well.

If you are in the market for a HVAC Coil Coating, choose the superior protection and heat transfer provided by THERMAL-XR®. If you want more information about the installation of this coating system, contact us today.