GMG’S BATTERY UPDATE: SIGNIFICANT BATTERY PERFORMANCE, CELL AND GRAPHENE PRODUCTION IMPROVEMENTS

BRISBANE, QUEENSLAND, AUSTRALIA – Graphene Manufacturing Group Ltd. (TSX-V: GMG) (“GMG” or the “Company”) is pleased to provide the latest progress and performance update on its Graphene Aluminium-Ion Battery technology (“G+AI Battery”) being developed by GMG and the University of Queensland (“UQ”) and the GMG battery grade graphene production quality program. Notably, this update includes information about GMG’s G+AI Battery regarding:

• GMG’s Graphene Aluminium-Ion Battery calculated energy density has increased to 290-310 Wh/kg, an increase of 93% since the last battery update on 22nd June 2021

• Power density has also increased to around 9,350 W/kg, a 33% increase since previous update

• Battery cell enhancements and repeatability

• Growing confidence in repeatability of battery grade quality graphene production at scale

• Next steps toward commercialisation

Improved Battery Technology Performance

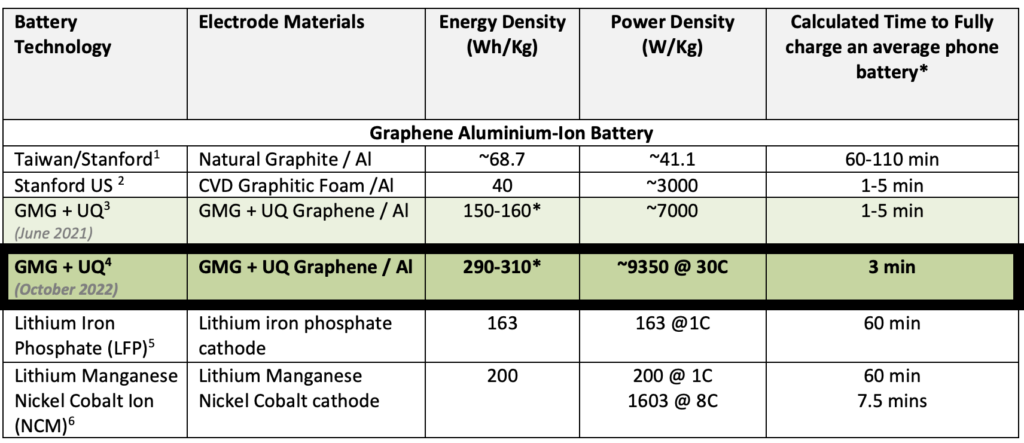

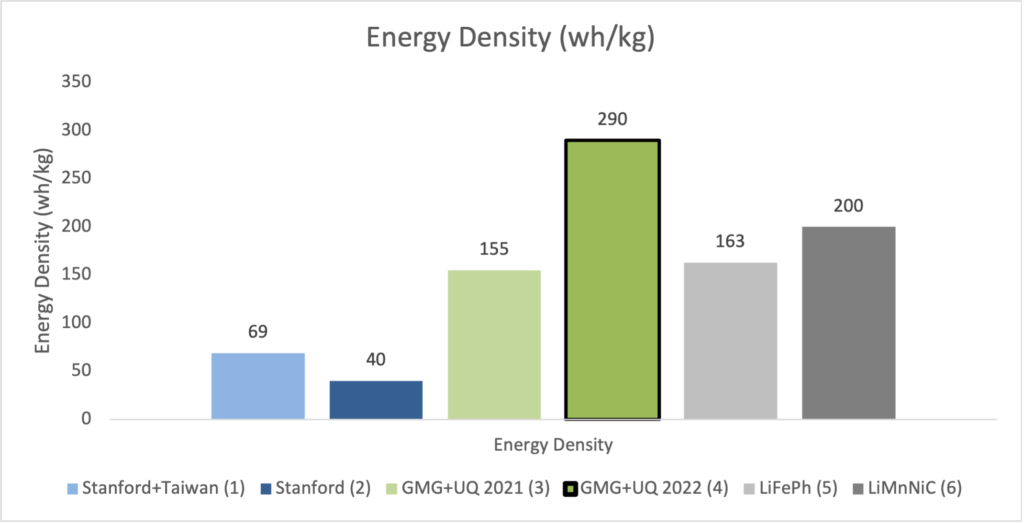

Ongoing development from GMG’s Battery Team has resulted in a significant increase in battery performance of GMG’s Graphene Aluminium-Ion Battery. Latest testing data has demonstrated a calculated energy density that has increased by 93% from 150-160 Wh/kg to 290-310 Wh/Kg since the last battery update on the 22nd of June 2021 (“Previous Announcement”).

Performance data presented in this release was calculated off GMG’s specific coin cell design and testing data, which has been separately verified by the Australian Institute for Bioengineering and Nanotechnology at the UQ as against other aluminium ion batteries and two commonly used lithium-ion batteries produced and used worldwide (see table and graph below).

Source: (1) Hongjie Dai, Nat. Commun., 2017, 8:14283, (2) Hongjie Dai, Nature, 2015, 520, 325, (3) and (4). University of Queensland validated GMG testing data.* (5). CATL 3.2V 150Ah LiFePO4 Battery Cell – LiFePO4 Battery (lifepo4-battery.com) on 29/09/22 (6). CATL 3.7V 65Ah NCM Lithium Battery Cell – LiFePO4 Battery (lifepo4-battery.com) on 29/09/22 7 *GMG testing data is based on industry standard estimate methodology – using a reducing factor of 2.3.

Source: (1) Hongjie Dai, Nat. Commun., 2017, 8:14283, (2) Hongjie Dai, Nature, 2015, 520, 325, (3) and (4). University of Queensland validated GMG testing data.* (5). CATL 3.2V 150Ah LiFePO4 Battery Cell – LiFePO4 Battery (lifepo4-battery.com) on 29/09/22 (6). CATL 3.7V 65Ah NCM Lithium Battery Cell – LiFePO4 Battery (lifepo4-battery.com) on 29/09/22 7 *GMG testing data is based on industry standard estimate methodology – using a reducing factor of 2.3.

GMG’s CEO Craig Nicol stated, “These results show the promise of GMG’s Graphene Aluminium Ion Battery in terms of performance on top of previously announced longevity and sustainability advantages. The outcome was the result of a large piece of work done by GMG’s Battery Team to repeatably make successful batteries, improve almost all of the various components of the battery and the successful transfer of intellectual property from the UQ team.”

Guy Outen, GMG’s Chair added, “I’m delighted with this battery performance update which reflects both the tremendous creativity and hard work of all involved as well as the possibilities of our G+Al Batteries, even at this early stage in their development. This is a significant step in the development of our G+AI batteries and we look forward to the next steps towards commercialisation.”

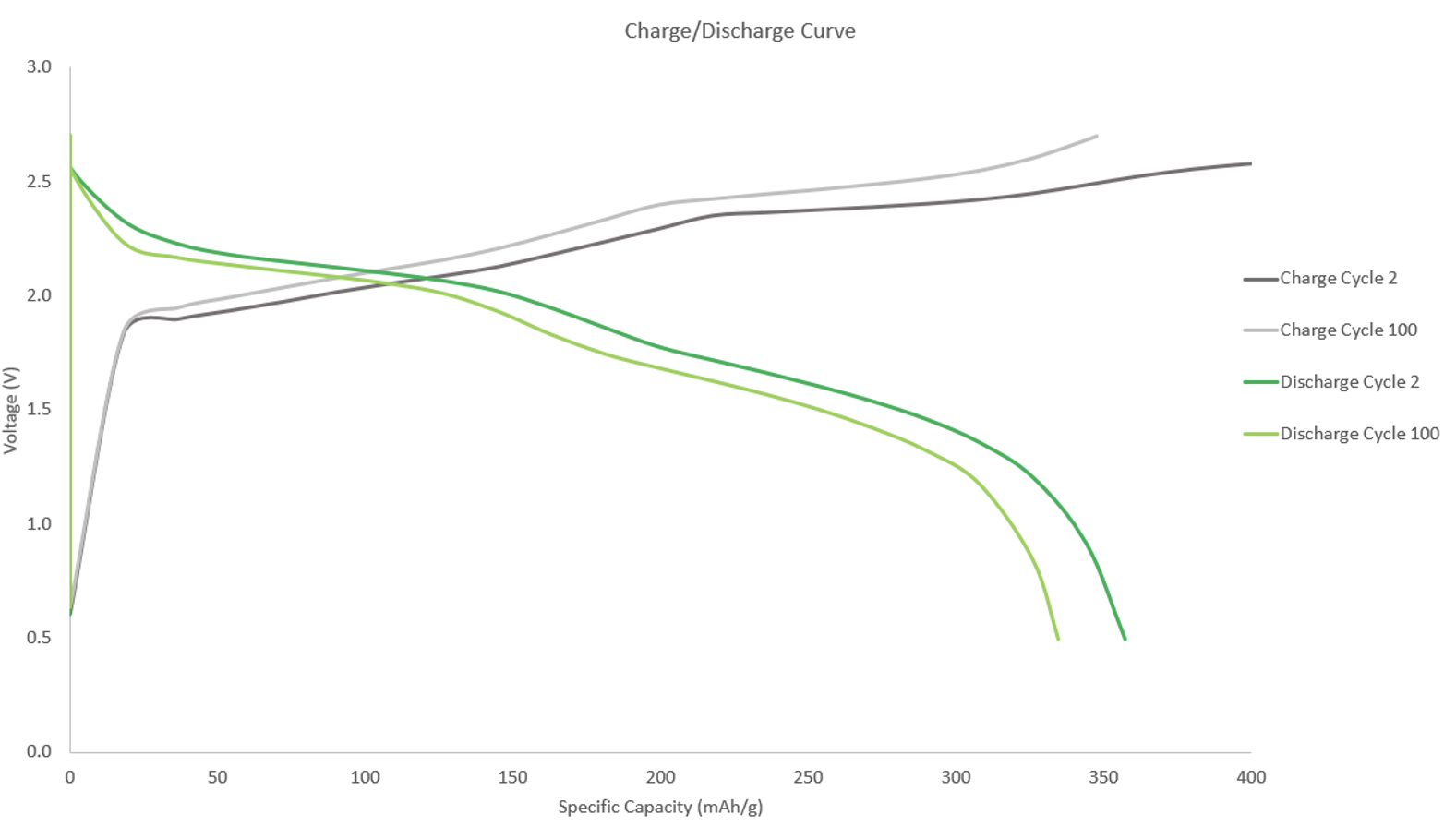

This performance improvement is a result of increasing the two main parameters since the Previous Announcement of:

- ~ 61% increase in the battery’s specific discharge capacity from 200 to 360mAh/gram and

- ~ 17% increase in the nominal voltage from 1.7 V to 2.0 V.

The following chart shows this latest performance achieved:

Source: GMG Testing. All testing was carried out on coin cells with GMG Graphene in Aluminium-Ion Battery ambient temperature cycling from 2.7V to 0.5V, 4.5 Coulomb (2.2 A/g) charge rate

This improvement in performance was associated with GMG successfully transferring the intellectual property from UQ’s laboratories to GMG’s Battery Development Centre and Battery Team. GMG now achieves a higher success and pass rate for the cells it makes for development and testing purposes which is a step towards commercial production.

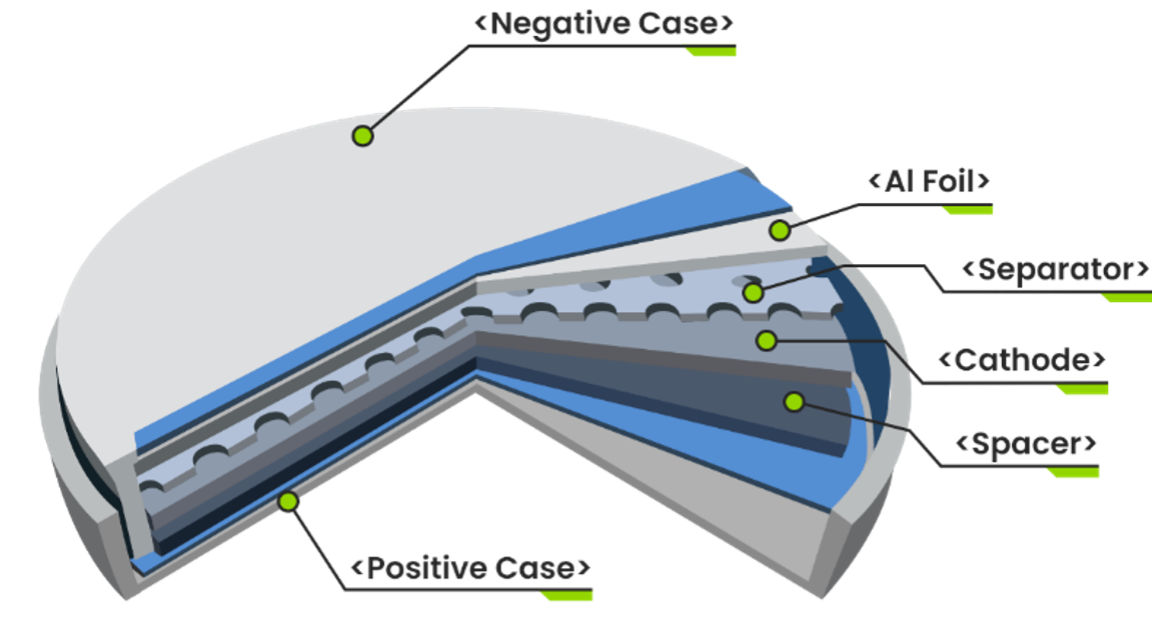

Figure 1: Typical G+AI Battery Coin Cell Design

GMG’s Battery Team has conducted work across the entire cell design (as per Figure 1) to improve performance, longevity, and ease of manufacture assembly including:

- Optimisation of the cathode substrate material selection and its preparation

- Repeatable graphene ink cathode preparation process

- Optimisation of selected cathode mixing fluid

- Optimisation of selected cathode binder

- Optimisation of the cathode thickness (given various loading options of low, medium and high)

- Reduction of internal resistance of the battery

- Stable and repeatable preparation and testing of the electrolyte to optimise cell performance

- Initial multilayer cathode design and production

- Initial multilayer cathode pouch cell design

- Present optimisation of the charging current for starting of the battery

- Present optimisation of the charging voltage for starting of the battery

- Successful removal of corrosion of the internals from the electrolyte

Repeatable Battery Grade Graphene Quality

GMG’s CEO Craig Nicol stated, “The Company’s confidence is growing in the GMG developed scalable process to make graphene from natural gas to a definable and tuneable graphene type for the GMG G+AI Battery in a repeatable fashion. Further testing is planned in the near term to further validate this confidence.”

GMG has also assessed battery performance with several different grades of GMG produced graphene using industry standard tests and have demonstrated repeatable and reproducible performance. GMG has increasing confidence that it has found an economically sustainable path to scale the graphene process. On this basis the Company will continue to work towards a final investment decision for first battery production.

GMG also compared the performance of the GMG made graphene, to graphene made by other processes by several other companies and identified GMG’s graphene as having more favourable specific discharge capacity, ie. a higher energy density performance. The Company expects ongoing iteration and improvement over time of both the graphene quality from the GMG graphene production process, as well as the G+AI Battery performance as GMG further develops, deploys and scales both of these technologies.

G+AI Coin Cell Development

The next steps for the coin cells (as seen in Figure 2) are to undertake further engineering and development activities to achieve a coin cell capacity for the desired product application(s) being targeted for initial customer sales.

Figure 2: G+AI Coin cell prototypes.

If this is achieved, subject to government approvals the Company’s Board will consider a Final Investment Decision (“FID”) for an automated coin cell factory and any (further) graphene production capacity expansion required. As part of the FID, GMG’s Board considerations will include, but not be limited to, binding customer sales contracts, the economic costs to build an automated coin cell factory and other operational-level production considerations. GMG is targeting a FID decision in 2023 and the latest production to commence in 2024.

As a precursor, GMG has already committed to invest AU$1.5 million into expanding and relocating its graphene production operations into an adjacent warehouse to its existing headquarters and Battery Development Centre (totalling 3,500 square meters) in Richlands, Queensland, Australia, as announced by GMG on 17 August 2022.

G+AI Pouch Cell Development

The next development steps for the pouch cell (as seen in Figure 3) will follow a similar sequence to the initial development of the coin cell.

When completed GMG will look to update the Technology and Product Road Map for the pouch cell and finalise the end application(s) for the initial market/customer for the pouch cells and therefore finalise the targeted pouch cell capacity. The Company continues to work under confidentiality agreements with a range of potential customers as input to this decision.

Figure 3: GMG Pouch Cell Prototype.

Upon finalising the target market, size and location of the plant and after various conditions are met, the Company may take FID on an integrated gas to graphene and automated pouch cell factory at likely a new location to account for its potential scale. The Company hopes to make significant progress on the pouch cell in 2023.

About GMG

GMG is a disruptive Australian-based clean-tech company listed on the TSXV (TSXV:GMG) that produces graphene and hydrogen by cracking methane (natural gas) instead of mining graphite. By using the company’s proprietary process, GMG can produce high quality, low cost, scalable, ‘tuneable’ and no/low contaminant graphene – enabling demonstrated cost and environmental improvements in a number of world-scale planet-friendly/clean-tech applications. Using this low input cost source of graphene, the Company is developing value-added products that target the massive energy efficiency and energy storage markets.

The Company is pursuing additional opportunities for GMG Graphene, including developing next-generation batteries, collaborating with world-leading universities in Australia, and investigating the opportunity to enhance the performance of lubricant oil and performance enhanced HVAC-R coating system.

For further information, please contact:

– Craig Nicol, Chief Executive Officer, and Managing Director of GMG

+61 415 445 223

– Leo Karabelas at Focus Communications Investor Relations (FCIR)

+1 647 689 6041

Cautionary Note Regarding Forward-Looking Statements

This press release contains “forward-looking information” and “forward-looking statements” within the meaning of applicable securities legislation. The forward-looking statements herein are made as of the date of this press release only, and the Company does not assume any obligation to update or revise them to reflect new information, estimates or opinions, future events or results or otherwise, except as required by applicable law. Often, but not always, forward-looking statements can be identified by the use of words such as “plans”, “expects”, “is expected”, “budgets”, “scheduled”, “estimates”, “forecasts”, “predicts”, “projects”, “intends”, “targets”, “aims”, “anticipates” or “believes” or variations (including negative variations) of such words and phrases or may be identified by statements to the effect that certain actions “may”, “could”, “should”, “would”, “might” or “will” be taken, occur or be achieved. Forward-looking information in this press release includes, but is not limited to, statements relating to the testing and validation of the graphene quality produced in the Company’s production process, the economical sustainability of scaling the graphene and battery production processes, the ongoing improvement of graphene quality from the GMG graphene production process and the G+AI Battery performance, the engineering and development of the coin cell and pouch cell with respect to the current battery performance estimates and calculations, the timing and considerations of potential FIDs, anticipated timelines for commercial production, anticipated next steps for the further development of the Company’s products, the development and viability of GMG’s production facilities, and the location of GMG’s production facilities. Forward-looking statements and information are subject to various known and unknown risks and uncertainties, including, but not limited to, the deployment of the Company’s resources, that the Company will not be able to test or validate the battery grade quality of graphene needed for its products, that it will not be economically sustainable to scale the graphene or battery manufacturing processes, that the quality of the graphene manufactured by GMG and the performance of the G+AI Battery will not set out to be as estimated, calculated or improve, that the Company will not be able to further develop the coin cell and pouch cell technologies, and the timing or results of any FID. Such risk factors may cause the Company’s actual results, performance or achievements to be materially different from those expressed or implied thereby, and are developed based on assumptions about such risks, uncertainties and other factors set out herein, including, assumptions regarding the Company’s ability to research, develop and test its products within anticipated timelines, and that results of testing and development data will be consistent with anticipated results and estimates, and the market demand for the Company’s products. Such forward-looking information represents management’s best judgment based on information currently available. No forward-looking statement can be guaranteed and actual future results may vary materially. Accordingly, readers are advised not to place undue reliance on forward-looking statements or information.